CNC Fabricating with Vertically Integrated Reclaimed Aluminum - CNC Materials

Published by Jordan Skole on 2/21/2022

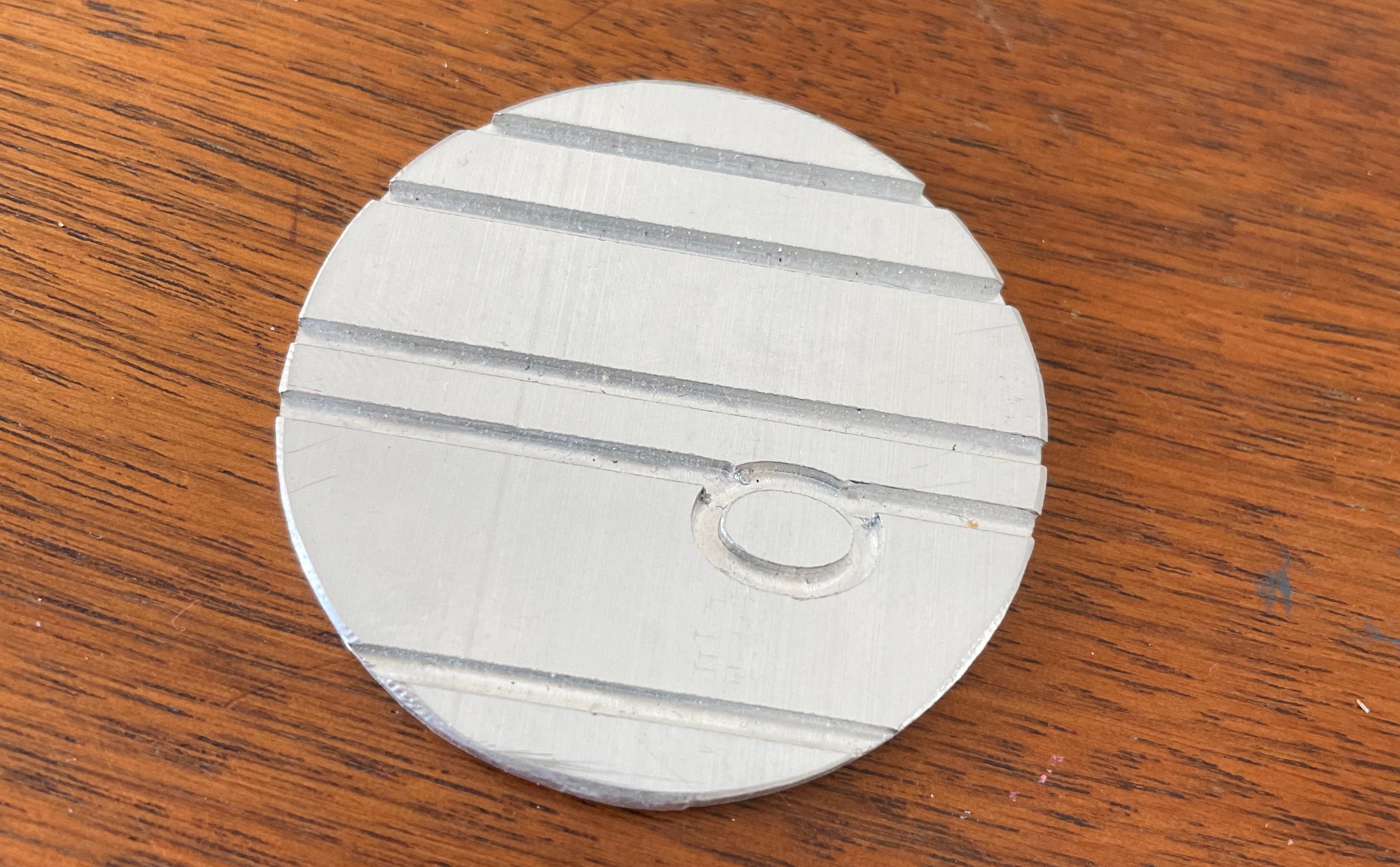

An aluminum jupiter coin I made for Jack from some Home Depot bar stock

Background

Aluminum is a wonderful material to work with. It is incredibly strong for it's weight, but also very soft and easy to work with.

The only downside is getting enough aluminum to work with can be a bit of a challenge. Flat bar is readily accessible and cheap, and works really well for projects like this Jupiter coin I made for jack.

I wanted something thicker though. Maybe to make super sturdy custom brackets for my truck, or larger pieces for 3-dimensional carvings.

- This 1 1/2" x 1/8" x 48" aluminum flat bar costs $13 and is great for making coins and other parts, but not for larger blocks. I would need to stack sheets or do some welding to fabricate thicker parts

- This 1" x 1" x 12" aluminum is only $13, but is still limited in size

Raw aluminum is all around us!

You just need to know how to get it into the form you need. In fact, there are approxametly 30 aluminum cans to a lb, and approxametly 70 aluminum cans in a kilogram.

I'm not really what ideas came first, but Ball recently released these aluminum cups and I am madly in love with them. They cost about $10 for 24 cups, and even though they say they are disposable/recyclable, they have held up in our house for several months so far on the top rack.

The big thing about them though is that they say "Infinitely Recyclable" all over the sides of them, which was what incepted me to consider melting my own blocks of aluminum for the CNC.

How do we turn 70 aluminum cans into a 1kg block of aluminum? With a little help from Amazon of course.

It turns out smelting aluminum is super easy, all you need is a smelting furnace. The one I got is going for $156 on Amazon right now.

If you have ever tried to brew beer, or deep fry a turkey, or made a tailgate-sized batch of chili you can melt your own aluminum. In fact, the furnace is basically just a turkey fryer filled with some fireproof rock-wool. This allows the inside of the furnance to retain it's heat and get REALLY hot.

You don't need much besides the furnace to get started, but after trying it out there are a few things I would recommend making sure you have on hand:

- The furnace kit itself - make sure it comes with a crucible and tongs

- A mold, I have seen folks on Amazon using muffin tins, but I grabbed a

- A pair of heavy-duty heat proof gloves. I picked up this pair from Home Depot for $11.

- A whole bunch of empty cans (read more in the annex at the end of the article) and other scrap aluminum

- An old cookie sheet or muffin tin - you will want something to put the hot stuff on

- A stainless steel slotted spoon - you will need something to scoop the slag off of the top. Slag is all of the not-aluminum that is also in your aluminum scrap.

There are a few other things you don't need, but I picked up anyway and would recommend.

- Some fire bricks - you can put these between the hot stuff and your masonry to prevent any masonry from cracking. I just used some regular bricks.

- A heavy-duty canvas apron - you don't want to get hit with a piece of aluminum splatter, but also you really need to look super cool.

- An infrared thermometer - The molds need to be heated to 500 degress farenheit before pouring the aluminum and this will help with that.